Cloud connectivity

Enable real-time data access and remote monitoring with cloud computing. Our solutions ensure scalability, security, and seamless system integration, allowing manufacturers to analyze operations from anywhere.

Sensor integration and data collection

Integrate IoT-enabled sensors for real-time production insights. Our smart sensor systems automate data collection, improve precision, and drive operational efficiency.

Remote Asset Monitoring, Live Data Analytics, Predictive Maintenance

Get instant visibility into production metrics. Our real-time monitoring tools help manufacturers detect anomalies, track equipment health, and optimize workflows proactively.

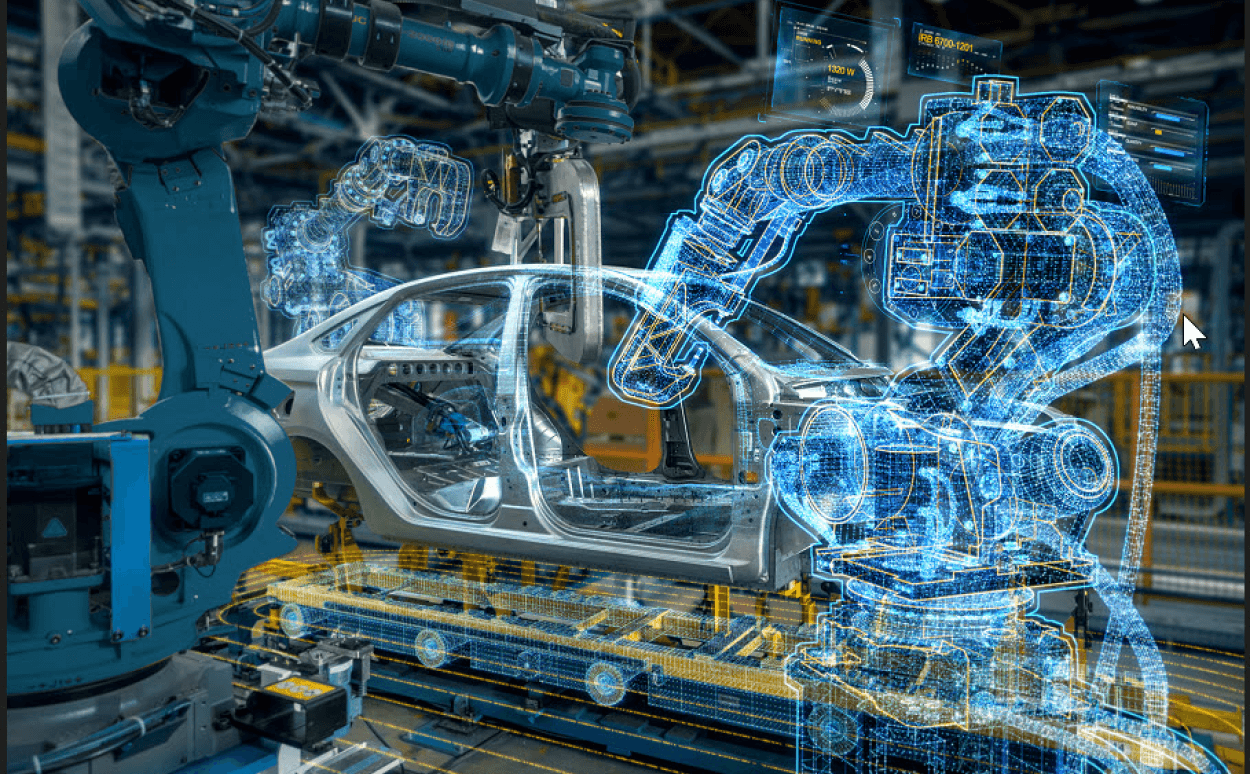

Digital Twin Technology, Virtual Manufacturing Models

Simulate, analyze, and optimize factory operations with digital twin technology. Create virtual replicas of physical assets to improve efficiency, test production scenarios, and reduce downtime.

Virtual Commissioning, Smart Factory Simulation

Minimize costly errors by simulating manufacturing processes before deployment. Virtual commissioning helps factories identify inefficiencies and refine automation setups without disrupting production.

Industrial Automation, System Integration

Seamlessly connect machines, software, and IoT devices. Our cross-platform solutions ensure smooth data flow between ERP, MES, and shop-floor control systems.

Industrial IoT, Smart Device Upgrades

Convert outdated equipment into IoT-enabled smart machines. We retrofit legacy devices with smart sensors, cloud connectivity, and AI-driven diagnostics, modernizing your factory without costly replacements.

Knowledge Graphs, Data Analytics for Manufacturing

Extract actionable insights from complex industrial data using semantic web technologies and knowledge graphs. Our data models leverage SPARQL queries to optimize manufacturing decisions.

Remote Asset Monitoring, Factory Digitalization

Monitor factory operations from anywhere with remote access tools. Get real-time updates on equipment performance and production metrics for quick decision-making.

MES Solutions, Digital Factory Automation

Optimize production processes with MES solutions. Our Manufacturing Execution Systems provide real-time tracking, production scheduling, and quality control.

Enhance operational agility with real-time analytics. Our solutions enable manufacturers to adjust process parameters dynamically for continuous shop-floor optimization.

Stay connected to your factory anytime, anywhere. Our mobile-friendly monitoring tools allow real-time tracking and instant alerts for critical systems.

Leverage AI to predict equipment failures before they occur. Our AI-powered diagnostic systems analyze real-time factory data to reduce unplanned downtime and increase efficiency.

Prevent costly manufacturing errors with virtual commissioning. Our solutions allow factories to simulate production processes and optimize efficiency before physical deployment.

Transform complex data into actionable insights. We integrate tools like Power BI and Node-RED to create interactive dashboards that drive data-driven decision-making.

Maximize efficiency with digital transformation solutions. Our approach enables manufacturers to streamline production, enhance visibility, and boost ROI.

Enabling digital transformation for your manufacturing setups through the most technologically sound and up-to date solutions, ensuring long-term reliability and continuous support

1

Our experts conduct in-depth site assessments to evaluate automation gaps, connectivity challenges, and digital transformation opportunities.

2

We develop a tailored Industry 4.0 roadmap, ensuring smooth implementation, scalability, and future-ready automation strategies.

3

Seamless execution from remote system development to on-site commissioning.Our team ensures flawless automation integration with minimal production disruption.

Partner with AXD for Smarter, More Efficient Manufacturing

Contact us for a free consultation on control system integration, PLC programming, and smart factory automation.

Talk to our expert