Our CNC solutions are designed to improve machining precision and operational efficiency. We offer custom retrofits to modernize your equipment, ensuring compliance with the latest industry standards.

Enhance Machine Performance with Modern CNC Control Systems

Upgrade your existing CNC controllers to state-of-the-art technology. We specialize in retrofitting outdated controllers, such as Sinumerik 840D PCU50, to modern IPC-based solutions, ensuring greater security, improved serviceability, and IoT compliance.

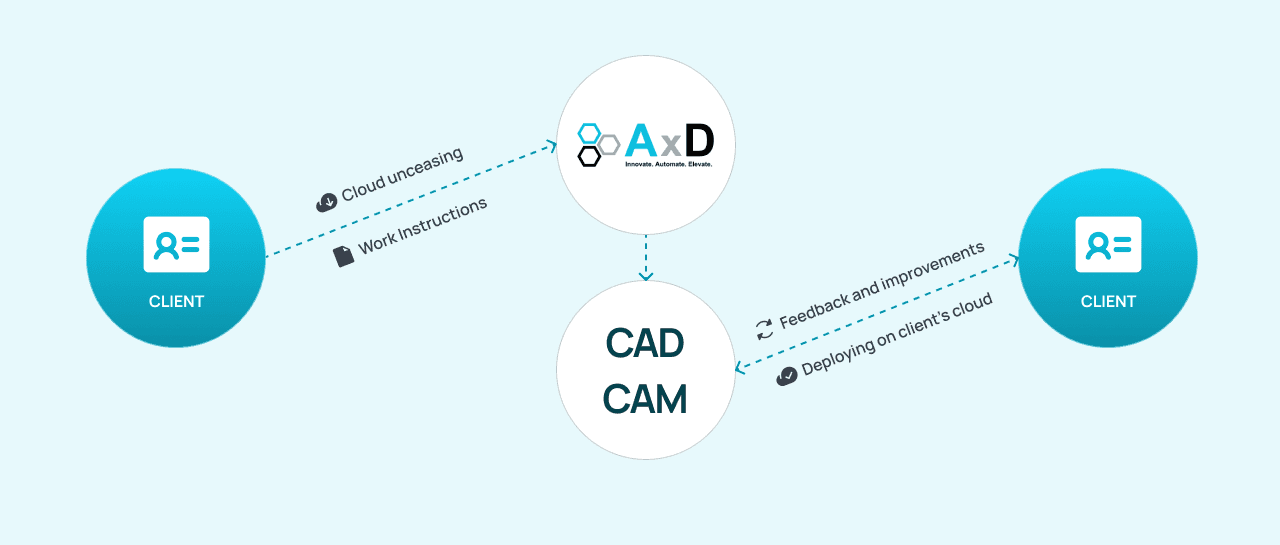

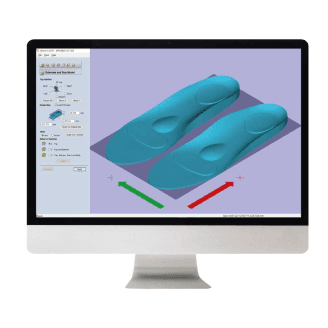

Remote CAM Programming for Seamless Operations

Our skilled team provides remote CAM programming services, optimizing toolpaths for die and mold production. Reduce dependency on in-house programming expertise and maximize efficiency.

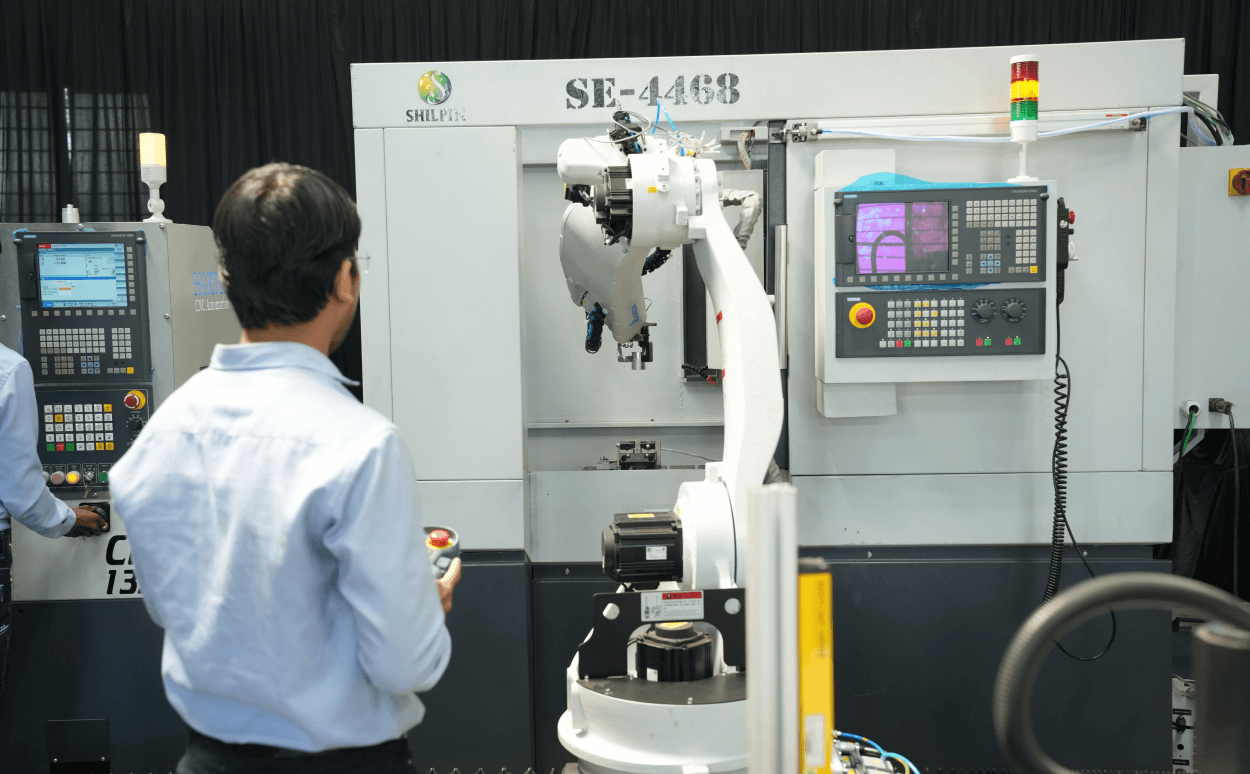

Automate Job Tending for CNC Machines

Improve production speed and consistency with our CNC automation solutions, including job tending robots. These robots handle part loading, unloading, and tool changes with minimal human intervention.

Digital Twins and Predictive Maintenance

Leverage digital twin technology to simulate and optimize machining processes before execution. Implement predictive maintenance software to minimize downtime and improve machine longevity.

AI-Driven Monitoring for CNC Machines

Harness the power of AI to detect issues before they cause failures. Our virtual commissioning tools allow you to test and refine manufacturing workflows without physical prototyping, saving time and materials.

Stay Connected to Your Machines Anytime, Anywhere

Monitor machine performance remotely using our advanced IoT solutions. Implement preventive maintenance strategies to extend equipment life and reduce operational costs.

Real-Time Data Analytics and Visualization

Utilize tools like PowerBI and NodeRED to transform raw machine data into actionable insights. Improve decision-making with intuitive dashboards tailored for industrial applications.

Expertise, Innovation, and Results - With decades of experience in CNC retrofits and digital manufacturing, we provide end-to-end solutions that enhance productivity and ensure long-term value.

Our digitlization portfolio empowers key stakeholders to monitor the manufacturing throughput and operations in real time, enabling them to dynamically alter process parameters for shop-floor optimization.

Get rid of the barrier to be physically present in the shop-floor, as we can now connect you to your setup from any part of the world through mobile applications built specifically to keep you informed at all times.

With a comprehensive data acquisition architecture and cloud integration, make more sense of your data by using AI models based on the digital twin of your setup.

By utilizing our virtual commissioning tools, you can get pre-empt any possible flaws in your workflow and fix them in the design stage instead of having to go through a fabrication cycle and losing on material costs.

Unlock actionable insights with powerful data visualization tools like PowerBI and NodeRED. These platforms transform complex data into intuitive dashboards and real-time analytics, enhancing decision-making and operational efficiency. Leverage these tools to streamline your industrial processes and drive smarter, data-driven outcomes.

Enabling key stakeholders to visualize and subsequently optimize manufacturing throughput via digitalization solutions

Partner with AXD for Smarter, More Efficient Manufacturing

Contact us for a free consultation on control system integration, PLC programming, and smart factory automation.

Talk to our expert