Requirement:

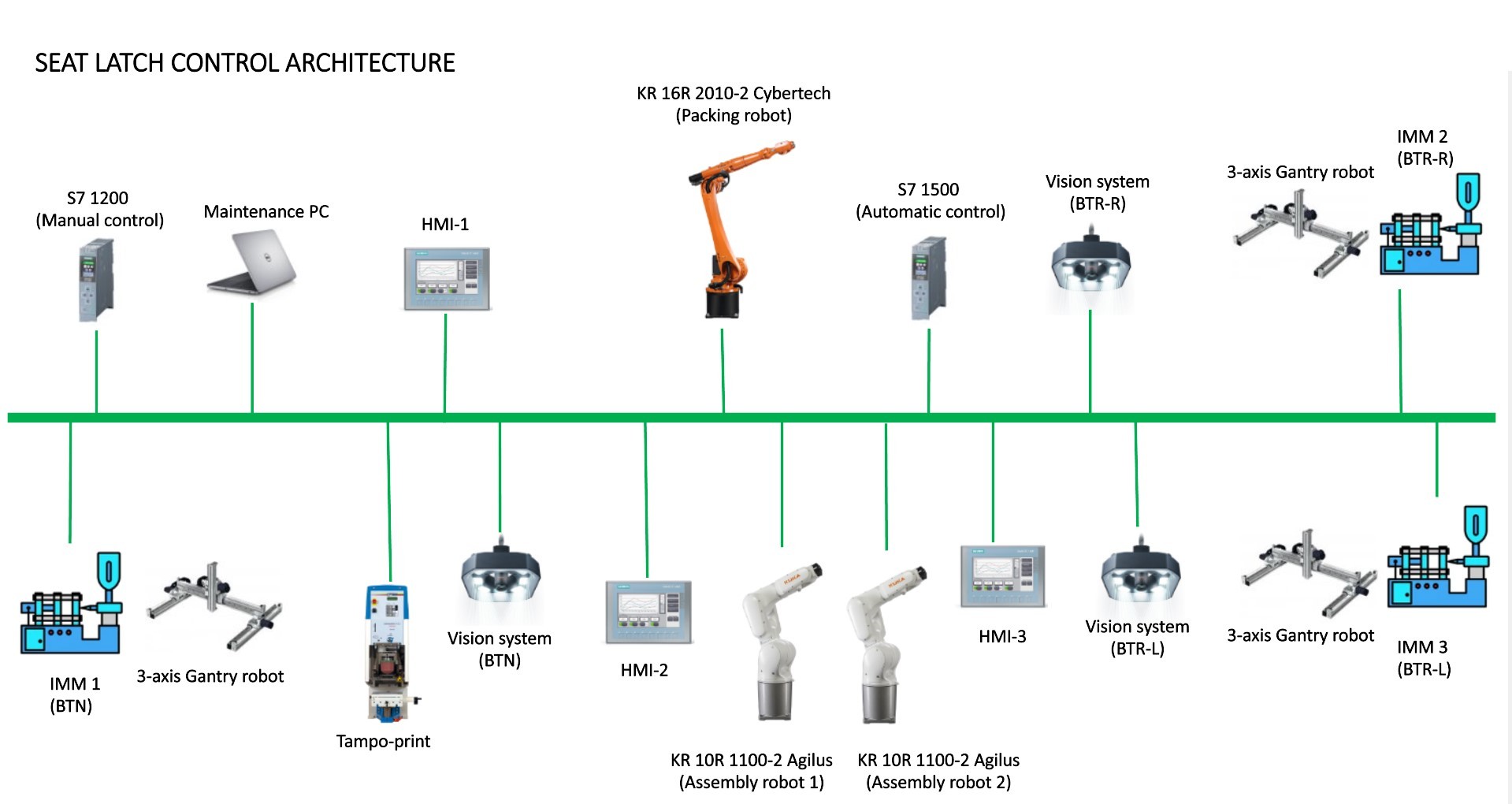

PLC programming and HMI development to enable robotic automation for a large-scale inspection assembly project of plastic injection molded parts

Salient Features:

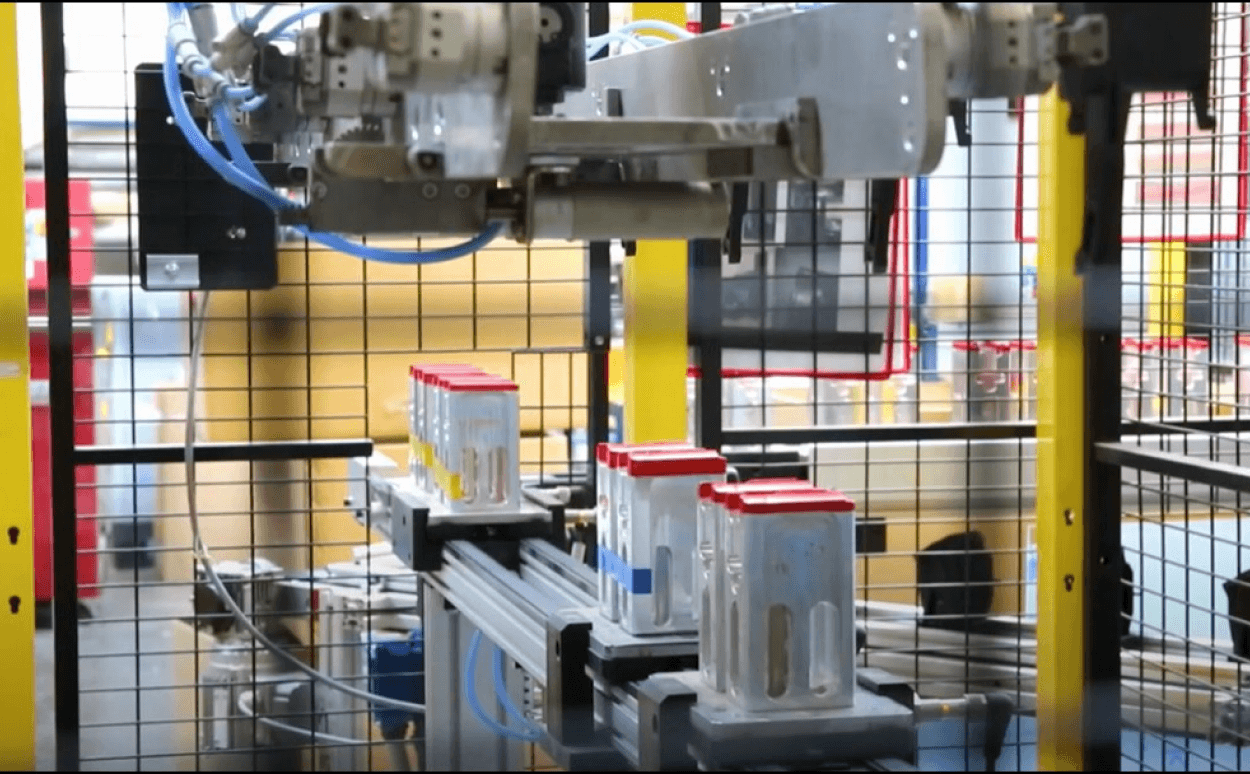

Production, assembly, inspection and packing of 14,400 parts a day with a cycle time of 12 seconds per assembly

Automation of 3 injection moulding machines, 3 6-axis robots, 3 gantry robots, industrial vision cameras, UV drying stations and a series of conveyor belts

HMI design for operator control and monitoring

Followed European EU-OSHA safety standards

Bottom-line Impact:

Annual throughput of 4 million assembled parts

Saved labor cost of ~20,000 euros annually by automating assembly process

On-site commissioning followed by off-site support from India